Menu

OPGW cables are typically custom designed to best match the optical, electrical, mechanical, quality and cost requirements of each individual project. This includes optimizing diameter, weight, breaking load and short circuit capacity. However, some “standard” designs are presented here for reference. The optical core is made of optical fibers covered by one or more loose buffer tubes that leave the fibers free from strain even at highest operating loads.

OPGW Cable Characteristic

Good mechanical and temperature performance

High strength loose tube that is hydrolysis resistant

Special tube filling compound ensure a critical protection of fiber

Specially designed compact structure is good at preventing loose tube from shrinking

Crush resistance and flexibility

Steel wire used as the central strength member

loose tube filling compound100% cable core filling

PSP enhancing moisture-proof

OPGW Cable Application

Optical fiber composite ground wire [OPGW] is suitable for installation on new power lines with double function of ground wire and

communication. Especially for installation on normal voitage and extra high voltage power lines. OPGW can replace conventional

ground wire of old power line with increasing fiber communication function. They conduct short circuit current and provide

lightning resistance.

OPGW Cable Features

1. Up to 144 fibers

2. Cable diameter and weight approximate with another ground wire. Less additional load to tower, high tensile strength.

3. Excellent stainless steel tube stranding technology make the fibers have good secondary excess length and allow the fibers free

movement in the tube. Which keeps the fiber stress-free while the cable is subjected to longitudinal stress.

4. Optical fibers are protected by stainless steel tubes.

5. Excellent security, good bullet resist performance.

6. ACSW, AAW and SST stranded design provide wide range combination of electrical conductivity and mechanical tensile strength.

|

Cable model

|

OPGW-60

|

OPGW-70

|

OPGW-90

|

OPGW-110

|

OPGW-130

|

|

Number /diameter(mm) of stainless steel tube

|

1/3.5

|

2/2.4

|

2/2.6

|

2/2.8

|

1/3.0

|

|

Number /diameter of AL wire(mm)

|

0/3.5

|

12/2.4

|

12/2.6

|

12/2.8

|

12/3.0

|

|

Number /diameter of ACS wire(mm)

|

6/3.5

|

5/2.4

|

5/2.6

|

5/2.8

|

6/3.0

|

|

Diameter of Cable (mm)

|

10.5

|

12

|

13

|

14

|

15

|

|

RTS(KN)

|

75

|

45

|

53

|

64

|

80

|

|

Cable weight (kg/km)

|

415

|

320

|

374

|

432

|

527

|

|

DC resistance(200C W/km)

|

1.36

|

0.524

|

0.448

|

0.386

|

0.327

|

|

Modulus of elasticity(Gpa)

|

162

|

96.1

|

95.9

|

95.6

|

97.8

|

|

coefficient of Linear thermal

|

12.6

|

17.8

|

17.8

|

17.9

|

17.2

|

|

expansion(1/℃×10-6)

|

|||||

|

Short circuit capacity (kA²s)

|

24

|

57.3

|

78.9

|

105.8

|

150.4

|

|

Max. operation temperature (℃)

|

200

|

200

|

200

|

200

|

200

|

|

Max. fiber count

|

48

|

32

|

48

|

52

|

30

|

We have professional technical support

Precise workshop production and production guarantee that

our cables will not be of different sizes and guarantee qualified quality

1).Packaging Details:

Packed by Drum on pallet or according to your requirements for Aluminium Conductor Steel Reinforced ACSR Cable.

2).Port:

Qingdao, Ningbo,Shanghai, Tianjin…

3).Lead Time:

| Quantity(Meters) | 1 – 5000 | >5000 |

| Est. Time(days) | 10 | To be negotiated |

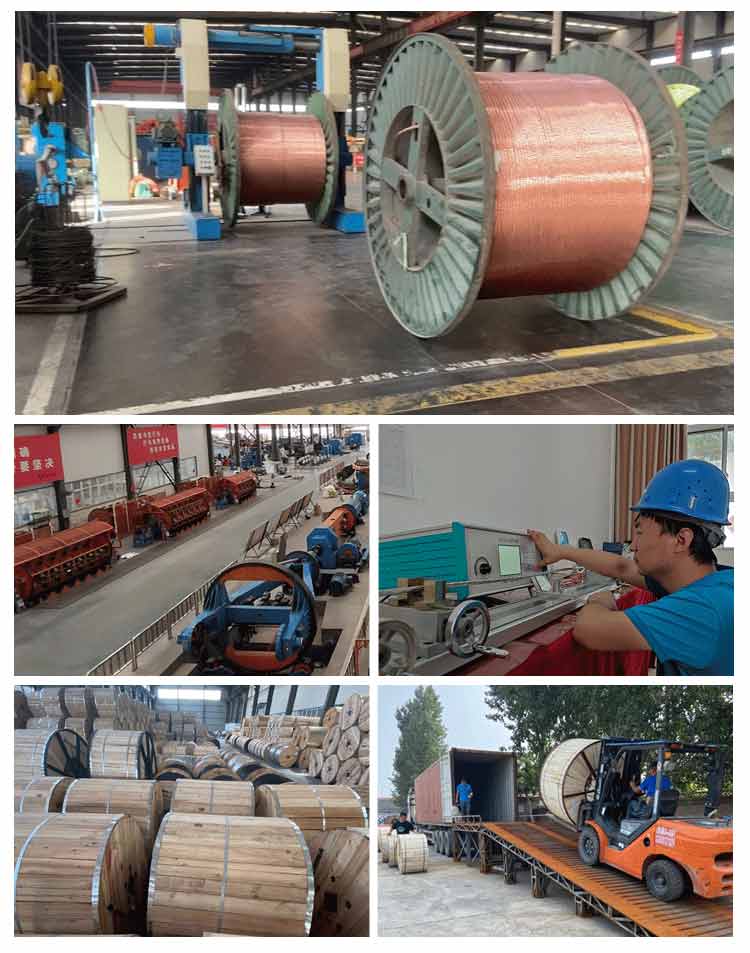

4).Picture Example:

Our Factory

Henan Aoguli Electric Co.LTD main products are Power cables up to 66kVAAC AAAC, ACS- R.ACCC conductors,ABC Cableelectric wires instrument cabletelecommunications cable Stay wirescable accessorycable jointcable fittings,and cable clampscable tie.

In the past decades,AOGULI built a wide sales network in global marketour major target mar kets are Middle EastAfricaSoutheast Asia America,EU. Our overseas projectsevolves State grid electricity,city/railway electric transportsubmarine cablesolar power plantsubstation,etc. We have 10 years exporting experienceWill keep goods safelysmootly and fast to your desination port or door to door.

Our Service