If you’re looking for information on a particular electrical cable, you’ve probably come across Concentric Cable. However, if you’re not familiar with this type of cable, read on for an introduction to its characteristics and composition. There are several different uses for this kind of cable, and knowing what they are can help you understand their use. The purpose of a concentric cable is to keep power moving, preventing blackouts. It can also be used as an electric service entrance or a feeder cable. The National Electrical Code (NEC) specifies the maximum service voltage of this cable, which is 600 V.

Concentric cables

The term “concentric” refers to a type of cable with two or more concentric conductors. The inner conductor is insulated with a neutral wire. Concentric cables are suitable for welding machines with a DC 200V or lower pulsating current value. They can be designed to meet specific requirements for the environment. They are also approved by the UK Power Networks Authority (UKPN).

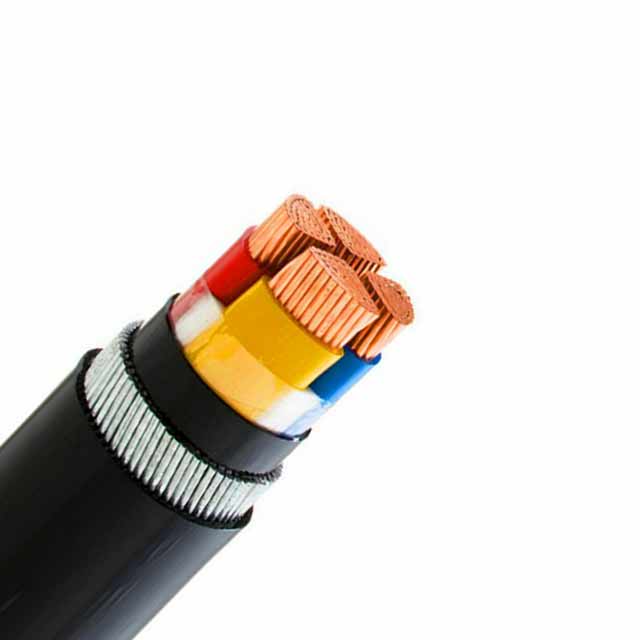

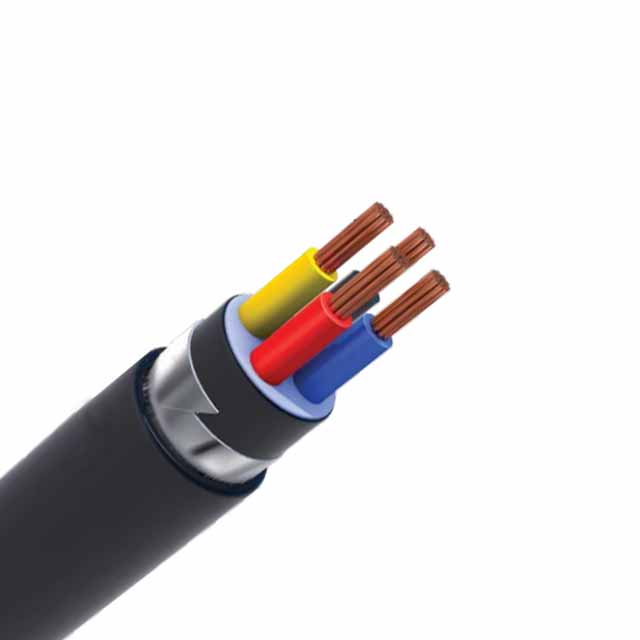

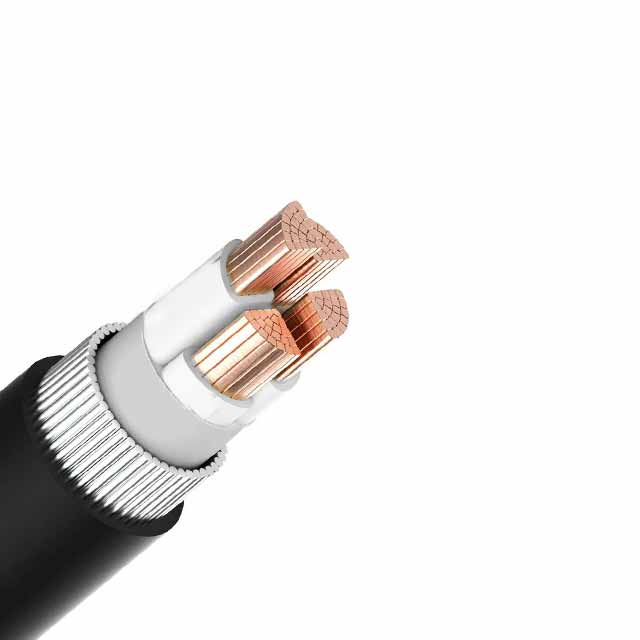

Concentric cables are generally made of copper or aluminum conductors. They are insulated with a plastic or paper reel, but may be produced in wooden or steel drums. They are available in various lengths and can be packaged to meet the needs of customers. Concentric cables are widely used in power distribution networks, panel, street lighting systems, and for energy supply. The National Electrical Code specifies the maximum operating temperature for this type of cable.

Distributors use Concentric cables for street lighting and sub main distribution. The cables have excellent anti-EMI and anti-lightning characteristics. The XLPE insulation helps to maintain high quality power supply. Furthermore, concentratic cables are suitable for direct burial. Further, they have low positive and zero sequence impedances, making them an excellent choice for direct burial. This cable is suitable for both overhead and underground wiring systems. The outer sheath of Concentric cables is black PVC.

While the concentric wires are not shielded, they provide an electrical screen. The copper conductors are partially or entirely exposed to the elements, but are in contact with a semi-conductor screen. This ensures a complete non-metallic cover over the cable. The insulation integrity is a top priority and should be of utmost importance in underground cable applications. It is important to understand how the cable is made before purchasing one.

Composition

Concentric cables are used for transmission of power in power lines with a rated voltage between 0.6 and 1kV. They come in two basic types: copper and aluminum. Each type has a maximum permissible operating temperature for the cable’s conductor (typically 90°F) and a maximum working voltage of 600 volts or more. These cables are usually insulated with PVC or XLPE.

A typical concentratic cable is made of multicore conductors, with an insulating layer between each conductor. These cables are commonly used for power distribution, street lighting, and sub mains in high-rise buildings. The insulation of these cables is typically made of XLPE, which provides excellent resistance to EMI and lightning. Despite the fact that they are made of multiple conductors, they are also suitable for direct burial in the ground.

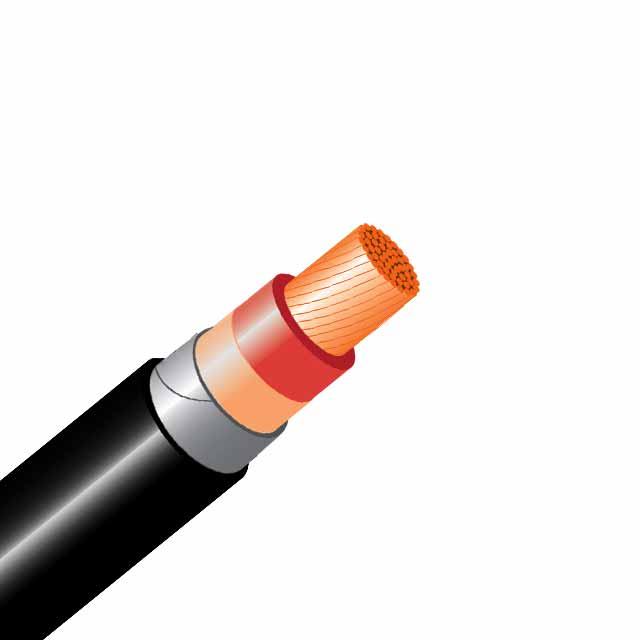

A common method of manufacturing a stranded cable is to feed a strip of semiconducting material across the outer circumference of the conductor. This strip is fed into the extrusion head while the insulating layer is extruded on top. The result is a stranded cable that is symmetrical. The tape element conforms to the inner conductor, and a minimum thickness is required for the cable to function at a medium voltage.

As a result, the design of composite cables and wire ropes is complex and challenging. The geometry of the structural elements can be different, and certain designing requirements cannot be met simultaneously. For instance, optimizing tensile stress behavior requires sacrificing cable flexibility. Additionally, there are limited experimental data on the behavior of composite cables and wire ropes, and these designers must validate their usual assumptions. However, this is not the end of the world.

Characteristics

The characteristic that distinguishes concentratic cables from other types of cables is their low positive sequence and zero sequence impedance. These characteristics improve the quality of power supplies. Compared to ordinary four-core cable, RG6 is also less reactive. It also exhibits good lightning strike resistance. Its working temperature range is 70°C to 90°C. This type of cable is suitable for use in both high-rise towers and street lighting systems.

Other characteristics of this type of cable include its high anti-EMI and lightning protection. Its low positive sequence impedance and uniform zero sequence impedance enhance the power quality of its supply. This cable also meets the requirements of BS7870, the British Standard for electricity cables. It is available in a variety of sizes, from four to 35mm in diameter. It is available in both single and multi-phase varieties and meets international standards.

The main characteristic of concentric cable is that it is suitable for shielding power cables. Its high-quality insulators and shielding material protect the cable from high-voltage shock. It also features a specialized conductor, which prevents the cable from short circuits. MV HV cables must be highly reliable to maintain their high-voltage operation. However, they should be tested for acoustic interference before installation.

A coaxial cable is an electrical cable with a center conductor suspended between two polyethylene discs every few centimeters. The copper core has a 2% ac resistance, which is much lower than the copper-based coax. These cables can be moderately bent and twisted, and they are often used with push-pull differential signalling. There are several disadvantages to coaxial cable, however.

Applications

Concentric cables are used in many different electrical applications, including power distribution, street lighting, and instrument panels. They are also suitable for direct burial. This type of cable features an insulated neutral conductor around the central phase conductor, acting like armor against “black losses” or electric power robbery. Listed in the National Electrical Code, concentric cables can be installed in both wet and dry locations. They also have a maximum temperature of 90°C and 600V, making them perfect for outdoor and sub main distribution.

Concentric Cable is available in several sizes and grades to suit different electrical applications. Single phase Concentric cables, for example, are used in overhead distribution systems as a connection between poles and the meter. They feature a unique helical concentric design. A concentric aluminum wire surrounds the phase core in a helical pattern, surrounded by a thermoplastic sheath. For more information, contact a supplier of seu concentric cable.

These cables are ideal for sub-main distribution, high-rise buildings, and more. They are also perfect for power lines and prevent electricity from escaping through energy meters. This prevents theft of electrical service from energy meters, which can be a problem in some cities. These thieves typically use metal claws or bite neutral and phase conductors. A concentric cable keeps this problem from happening. Therefore, installing concentric cables is a smart move for any commercial building.

Unlike traditional conductors, CN cables are completely shielded against sunlight. They are also highly resistant to heat and cold. They are also available in a wide variety of colors and styles. They are used in a wide range of commercial and residential underground feeder systems and cable voltages of 5kV to 46kV. Solar power distribution is another application for CN cables. The list of applications for this cable is nearly endless.

Cost

The cost of Concentric Cable depends on several factors, including the type of cable, the amount of conductors used, and the voltage rating of the system. Concentric cables are normally single solid wires, but they may also be stranded. For three-phase systems, concentric cables can have plural conductors. They can also be constructed of two parallel insulated conductors, with concentric wires encircling them.

The two most common types of Concentric Cables are single-core and multicore. Both types are made from solid copper conductors. They both have an insulating layer between the cores, which is typical of most types of cable insulation. In addition, Concentric Cables are commonly used in energy supply systems, including sub mains in high-rise towers, street lighting systems, and distribution networks. A typical Concentric Cable consists of a single-core solid copper phase conductor, XLPE-insulated neutral conductor, and an outer sheath of black PVC.

Concentric Cable is available in a range of sizes and is designed to meet international standards. BS7870 is the international standard for electrical cables. The company also makes split concentric cables for power supplies with separate PE and N conductors. Split concentric cables are only used near a power supply and are only connected at the building entrance point. You can purchase Concentric Cable for your system at any local hardware store or electrical supply outlet.

When comparing the two types of Concentric Cable, you will find that one of the highest quality cables is the RG6 type. It features lower reactance and improved power supply. RG6 cable has a higher operating temperature than ordinary four-core cables. It is also resistant to lightning strikes. You can even purchase an armored Concentric Cable with a deformation-resistant shield. Its maximum temperature is about 90 degrees Celsius, but is suitable for power lines.