What is Cable Accessory? The cables and their accessories are the life blood of your network. From connecting conductors to cable screens to protecting them from moisture, these accessories are essential to your network. You may have many different kinds of cables. But no matter what kind of cable or connector you’re using, you’ll need a cable accessory for that. So let’s take a look at what these accessories are and how they’re used.

Cable accessories serve as the lifeblood of your network

High quality Cable Accessories will ensure reliability, help you reduce power interruptions, and improve the working environment. The advancement of cable technology has resulted in more reliable and cost-effective undergrounding of network infrastructure. However, a cable accessory failure during service can be attributed to several factors, the most common of which is improper installation. Hence, proper training of your network technicians and the use of high-quality cable are required to minimize the chances of such occurrences.

Cable accessories help in keeping cables organized. Cable covers and dividers help to distinguish different wires. Various types of cable protectors provide ease of installation and come in different colors. Various kinds of cable organizers are available, including single wire protectors and bundle protectors. Additionally, cable management supplies include racks and raceways. The latter are perfect for home networking. This article will discuss different types of cable organizers and their uses.

They connect conductors to cable screens

Cable accessories connect conductors to cable screens in a variety of ways, but the most reliable connection is usually achieved with a hard-wired connection. Military-style connectors are an excellent choice because of their solid 360-degree connection. Commercial connectors are a better option, but they must also have a tin-plated shell. The best connection is made when the screen makes 360-degree contact with the screened conductive backshell.

The connection of screen wires to conductors is important to reducing EMC. The current flowing through the screen is often out of phase with the conductor’s current. Therefore, the screens must be grounded at both ends. If they cannot, the screens can be damaged. The CT is the best choice for EMC-compliant installations. This type of connection helps minimize the coupling between the conductors and the environment.

Some cable accessories require parking the components onto the cable before completing installation. The outer sheath must be clean and dry before starting work. When installing cable accessories, always ensure that you have a protective covering over the cable. Some manufacturers suggest using plastic bags to protect the cable outer sheath. If the insulation of the cable is not clean, then it is important to use a cleaning agent to clean the cable core.

In high-voltage applications, high-quality cables require special types of accessories. They must provide protection against moisture and mechanical damage. Accessories also must be simple and easy to install. Safety is another important consideration. High-quality cable accessories combine a variety of materials and installation technologies. Therefore, each cable accessory has its own distinct set of requirements. The best way to select cable accessories depends on the construction of the cable.

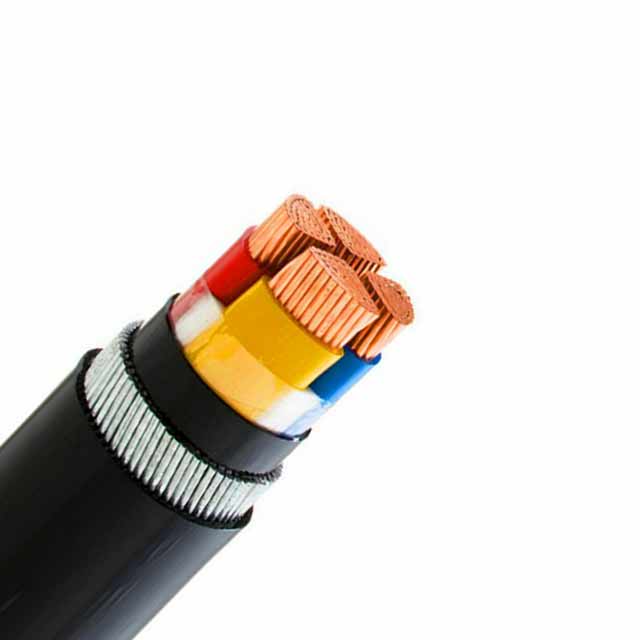

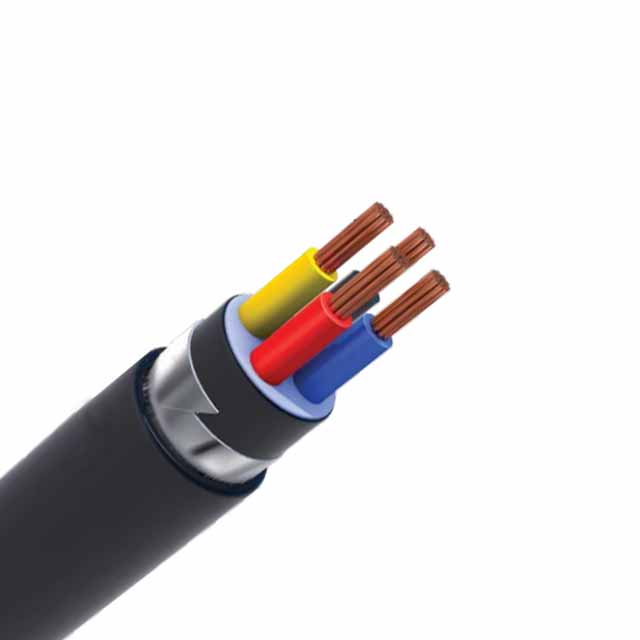

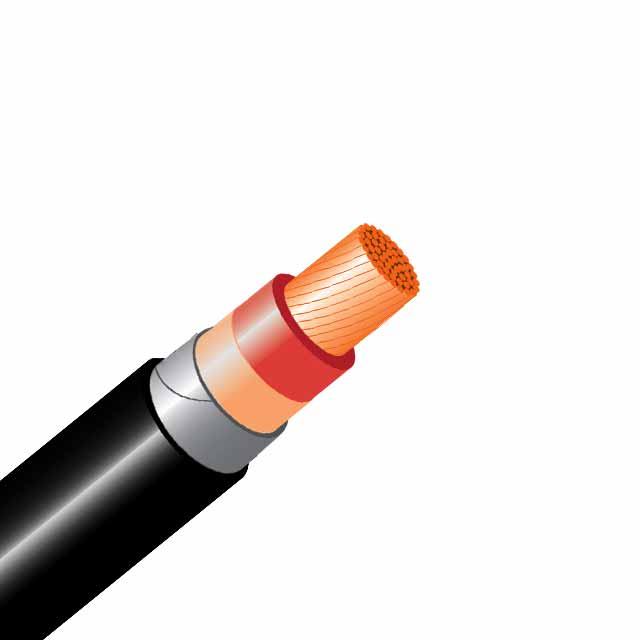

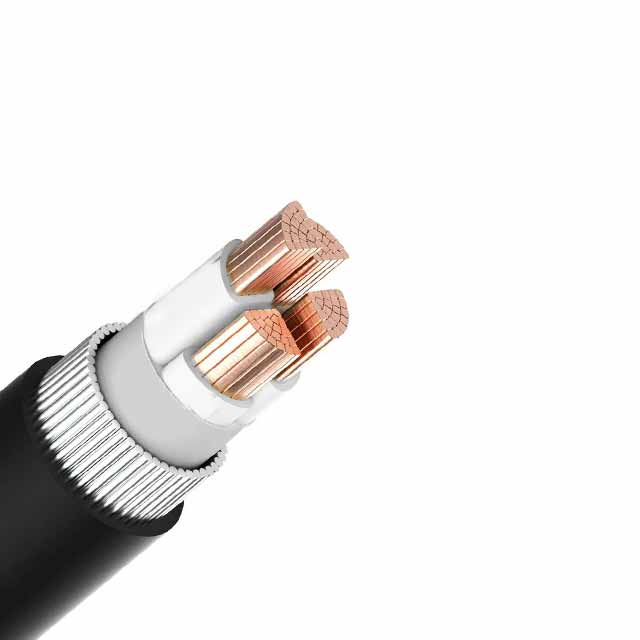

Extruded polymeric cables generally have a polyethylene or PVC outer sheath. The conductive screen is made of copper wires or strips. Some older cables are made with a conductive fabric tape. A conductive fabric tape is used to cover the exposed conductive paint. A suitable tool is needed to remove the excess screen length. However, it is recommended to test the tool with a spare cable before using it on your cables.

They protect the cable screen from water

The main requirements of a Cable Accessory are the long life and easy installation. These accessories must protect the cable screen from water and other hazards while being easy to install. Another important technical requirement is safety. High-quality cable accessories use a variety of installation and insulation technologies to ensure the durability and reliability of the products. The different types of Cable Accessory are discussed below. You should carefully choose the one that is most suitable for the type of cable screen you are installing.

Depending on the type of cable screen, you should choose a solution that will effectively protect it against water. Single-core cables are particularly susceptible to water ingress due to the gap between screen wires. Water swellable tapes applied longitudinally under the sheath layer can effectively prevent water from entering the cable. Non-ferromagnetic sheaths made of lead or stainless steel can prevent water from entering the conductor.

Cable accessories must be water-proof to provide a reliable medium-voltage distribution network. Water is the main factor in degrading cable insulation. Poor joint and shield tightness can let water in, compromising the reliability of the system. Several construction methods are available to protect the critical inner joint and system from water. For example, cable accessories can be made of polymeric material for increased flexibility. These materials are extremely versatile and can be used in a variety of applications.

Fire-resistant cables are also required to meet strict standards. The cable accessories must be capable of maintaining system integrity for at least 180 minutes. Fire resistance requirements are more stringent than fire retardance and require different design considerations. Cable accessories should meet the IEC-60331 standard for fire-resistant cables. One of the most demanding environments for cable accessories is the containment areas of nuclear power plants. The electrical systems must be capable of functioning under extreme conditions such as nuclear reactor meltdowns.

They are used to connect conductors to cable conductors

A variety of cable accessories are available. These include cable trays, cables, and strain relief devices. Various cable types have different designs, and all require different cable accessories. Different cables may require a different type of cable screen, which will affect their reliability. Some cables use copper tape screens, others use welded aluminum sheaths, and still others may use a combination of copper wire screen and laminated aluminum screen.

Polymeric cables are the most common and cost-effective solution for most AC, DC, and optical cable applications. Failure rates of cable systems are often caused by third party mechanical damage or improper installation of cable accessories. Manufacturers of cable accessories have the ability to influence failure rates through better materials and fault-tolerant installation techniques. AFL has developed an extensive selection of polymeric cables. If you are looking for cable accessories, look no further than AFL.

The most important feature of cable accessories is their long service life. They must be easy to install and protect cable conductors against moisture and mechanical damage. Safety is another important factor to consider. Different cable accessories may require different insulation materials and installation technologies. Regardless of the type, it is essential to choose cable accessories that meet the requirements of your application. If you’re looking for the perfect accessory for your application, we have compiled a list of the most important features to consider before you choose a cable accessory.

Cable accessories are essential for connecting cables and connecting conductors. The most common types of cable connectors are mechanical connectors. These cables have a low bending radius and a high mechanical strength. They also provide good flexibility, and are suitable for outdoor use. The maximum operating temperature of insulated cable is 85degC at 5kV. You should check the connectors for the maximum voltage required.

Some cables have special jacketing materials to prevent fires from spreading, but they will still burn. A fire that breaks out in a group of cables can be disastrous. Fire retardant coatings and noncombustible boxes are available to help prevent fires from spreading among combustible cables. MI cable can also be used as plenum cabling in a building without an overall nonmetallic jacket.