Menu

All Aluminium Alloy Conductors (AAAC) is a concentric-lay-stranded conductor consisting of aluminum-alloy wires (6201-T81)available in single layer and multi-layer constructions. As compared to a conventional ACSR conductor, the lighter weight,comparable strength & current carrying capacity, lower electrical losses and superior corrosion resistance have given AAAC a wide acceptance in the distribution and medium & high voltage transmission lines.

AAC Conductor Application

Used as bare overhead conductor for primary and secondary distribution. Designed utilizing a high-strength aluminum-alloy to achieve a high strength-to-weight ratio; affords good sag characteristics.

(1)AAAC conductors are extensively used for overhead distribution and transmission lines adjacent to ocean coastlines where there can be a problem of corrosion in the steel of an ACSR construction.

(2)The aluminum alloy conductors are used in replace of single-layer ACSR conductors to reduce power loss in overhead distribution and transmission lines, when replacing the aluminum conductor steel reinforced , the AAAC can save 5-8% of the construction cost.

(3)AAAC referred to have higher strength but lower conductivity than pure aluminum Being lighter, alloy conductors can sometimes be used to advantage in replace of the more conventional ACSR

AAAC Conductor Application

Standard 6201-T81 high strength aluminum conductors, conforming to ASTM Specification B-399, are concentric-lay- stranded, similar in construction and appearance to 1350 grade aluminum conductors. Standard 6201 alloy conductors are similar to other alloy conductors commercially known as Ardival, Aldrey or Almelec.They were developed to fill the need for an economical conductor for overhead applications requiring higher strength than that obtainable with 1350 grade aluminum conductors, but without a steel core. The DC resistance at 20°C of the 6201-T81 conductors and of the standard ACSRs of the same diameter are approximately the same. Conductors of the 6201-T81 alloys are harder and, therefore, have a greater resistance to abrasion than conductors of 1350-H19 grade aluminum.

AAAC Conductor Features

Aluminum alloy conductors have a number of advantages over the use of the ACSR or AAC(all aluminum conductors).

Lower power losses than for equivalent single aluminum-layer ACSR conductors. (The inductive effect of the steel core in the ACSR is eliminated).

• Simpler fittings than those required for ACSR.

• Excellent corrosion resistance in environments conducive to galvanic corrosion in ACSR.

• Strength and sag approximately the same as for equivalent 6/1 and 26/7 ACSR conductors.

• Outside diameters are the same as for standard ACSR conductors, permitting interchangeability of fittings.

• Greater resistance to abrasion than that for 1350 wires in all-aluminum or ACSR conductors.

• High tensile strength as compared to AAC conductor.

• Higher conductivity as compared to ACSR conductor.

| All Aluminium Alloy Conductors(AAAC) ASTM B 399 | |||||||

| AREA | Stranding | Wire Dia. | Approx. overall diameter | Weight | Nominal Breaking Load | Nom. DC resistance at 20 Deg. | |

| Nominal | Actual | (mm) | (mm) | (kg/km) | (kN) | (ohm/km) | |

| AWGorMCM | (mm2) | ||||||

| 6 | 13.3 | 7 | 1.554 | 4.67 | 37 | 4.22 | 2.5199 |

| 4 | 21.15 | 7 | 1.961 | 5.89 | 58 | 6.71 | 1.5824 |

| 2 | 33.63 | 7 | 2.474 | 7.42 | 93 | 10.68 | 0.9942 |

| 1/0 | 53.48 | 7 | 3.119 | 9.36 | 148 | 16.97 | 0.6256 |

| 2/0 | 67.42 | 7 | 3.503 | 10.51 | 186 | 20.52 | 0.4959 |

| 3/0 | 85.03 | 7 | 3.932 | 11.8 | 234 | 25.86 | 0.3936 |

| 4/0 | 107.23 | 7 | 4.417 | 13.26 | 296 | 32.63 | 0.3119 |

| 250 | 126.66 | 19 | 2.913 | 14.57 | 349 | 38.93 | 0.2642 |

| 300 | 152.1 | 19 | 3.193 | 15.97 | 419 | 46.77 | 0.2199 |

| 350 | 177.35 | 19 | 3.447 | 17.24 | 489 | 52.25 | 0.1887 |

| 400 | 202.71 | 19 | 3.686 | 18.43 | 559 | 59.74 | 0.165 |

| 450 | 228 | 19 | 3.909 | 19.55 | 629 | 67.19 | 0.1467 |

| 500 | 253.35 | 19 | 4.12 | 20.6 | 698 | 74.64 | 0.1321 |

| 550 | 278.6 | 37 | 3.096 | 21.67 | 768 | 83.8 | 0.1202 |

| 600 | 303.8 | 37 | 3.233 | 22.63 | 838 | 91.38 | 0.1102 |

| 650 | 329.25 | 37 | 3.366 | 23.56 | 908 | 97.94 | 0.1016 |

| 700 | 354.55 | 37 | 3.493 | 24.45 | 978 | 102.2 | 0.0944 |

| 750 | 380.2 | 37 | 3.617 | 25.32 | 1049 | 109.6 | 0.088 |

| 800 | 405.15 | 37 | 3.734 | 26.14 | 1117 | 116.8 | 0.0826 |

| 900 | 456.16 | 37 | 3.962 | 27.73 | 1258 | 131.5 | 0.0733 |

| 1000 | 506.71 | 37 | 4.176 | 29.23 | 1399 | 146.1 | 0.066 |

We have professional technical support

Precise workshop production and production guarantee that

our cables will not be of different sizes and guarantee qualified quality

1).Packaging Details:

Packed by Drum on pallet or according to your requirements for Aluminium Conductor Steel Reinforced ACSR Cable.

2).Port:

Qingdao, Ningbo,Shanghai, Tianjin…

3).Lead Time:

| Quantity(Meters) | 1 – 5000 | >5000 |

| Est. Time(days) | 10 | To be negotiated |

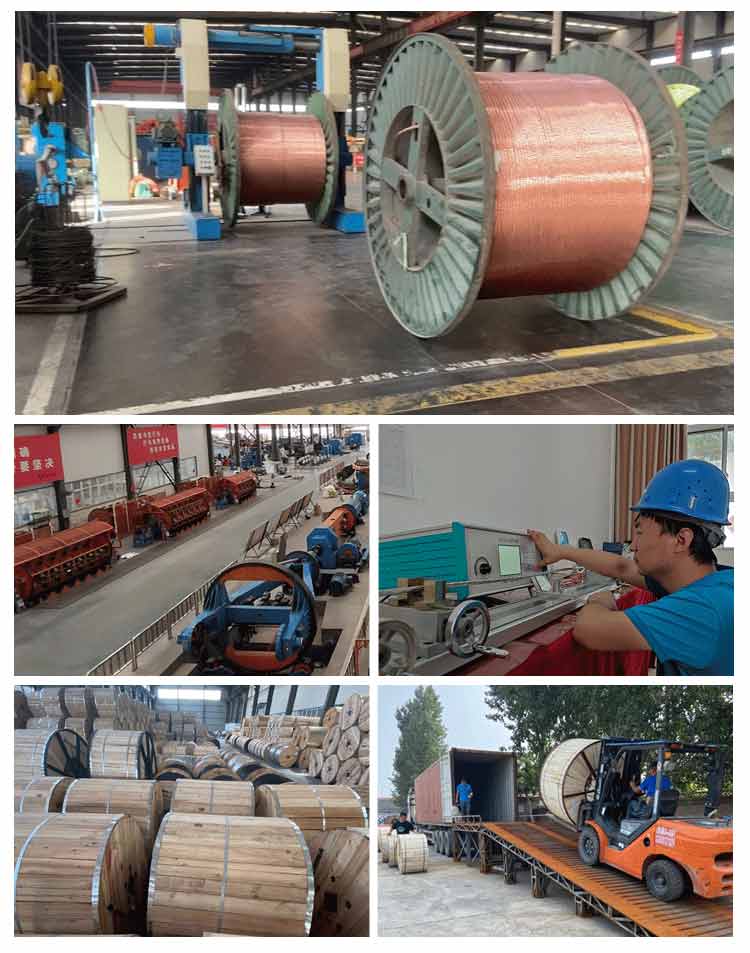

4).Picture Example:

Our Factory

Henan Aoguli Electric Co.LTD main products are Power cables up to 66kVAAC AAAC, ACS- R.ACCC conductors,ABC Cableelectric wires instrument cabletelecommunications cable Stay wirescable accessorycable jointcable fittings,and cable clampscable tie.

In the past decades,AOGULI built a wide sales network in global marketour major target mar kets are Middle EastAfricaSoutheast Asia America,EU. Our overseas projectsevolves State grid electricity,city/railway electric transportsubmarine cablesolar power plantsubstation,etc. We have 10 years exporting experienceWill keep goods safelysmootly and fast to your desination port or door to door.

Our Service