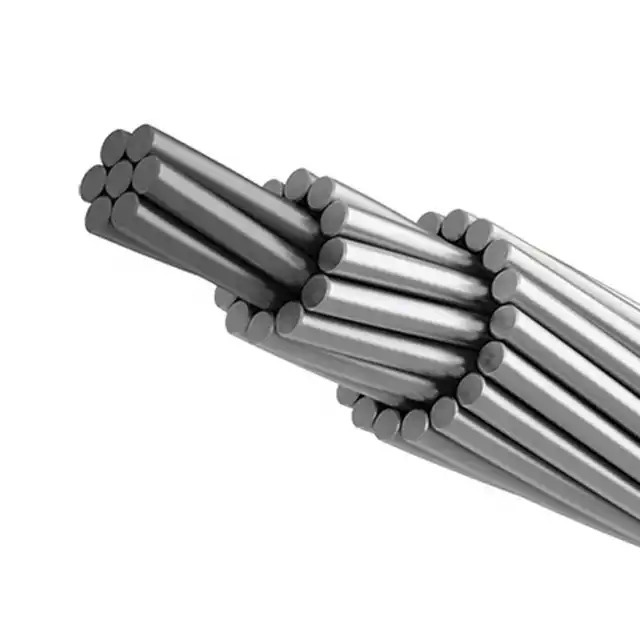

What is AAC cable? Let’s talk about its uses and benefits. There are many types of cables that are available, including standard, non-standard, and AAC cables. This article will explore the differences between these cable types so you can choose the right one for your application. AAC stands for All Aluminium Conductor, and ACSR stands for Aluminium Conductor Steel Reinforced. If you’re looking for high-quality cables that are affordable, AAC is the right option.

All Aluminium Conductor

All Aluminium Conductor steel-reinforced cable is a high-strength stranded conductor made of high-purity aluminium. High-purity aluminium is chosen for its good conductivity, low weight, and low cost. These cables also have excellent corrosion and mechanical stress resistance. They are widely used in overhead power lines. Read on to find out more. What is an Aluminium Conductor?

All Aluminium Conductor is also called All Aluminium Alloy Conductor, Aluminium Conductor Steel Reinforced, and AISI 66. The material’s tensile strength depends on the aluminum in the cable. It is mainly reinforced with steel and has a continuous operating temperature of 75 degC, at which aluminium starts to anneal and soften. However, aluminium-conductor steel-supported cable is suitable for use in temperatures as high as 250 degC.

Tenaga Cable Industries Sdn Bhd was established in 1957 as Malayan Cables Limited. Its products comply with the Electricity Regulations 1994 of the Energy Commission of Malaysia. Olympic Cable Company is also a Malaysia-based manufacturer of cable. However, this company is not the only company producing All Aluminium Conductor cable. Many buyers have been able to find a quality Chinese supplier through All Aluminium Conductor cable. Listed below are a few of the top suppliers of All Aluminium Conductor cable.

One of the main benefits of ACSR is its low hysteresis losses. This loss is caused by the atomic dipoles in the steel core changing direction. But, ACSR conductors can minimize this loss by employing even numbers of layers of aluminium. The opposing lay conductors cancel out each other’s magnetic fields, thereby reducing the risk of hysteresis losses.

Another advantage of TP conductors is that they are cheaper to install. They are used where high winds are prevalent and freezing temperatures are common. Because they can withstand extreme conditions, TP conductors can be used in buildings with high ceilings. They can also withstand earthquakes and ice loads. And, they can withstand high-tension levels without Stockbridge-type dampers. They can also be used in high-tension applications and have a very low flexicity.

Aluminium Conductor Steel Reinforced

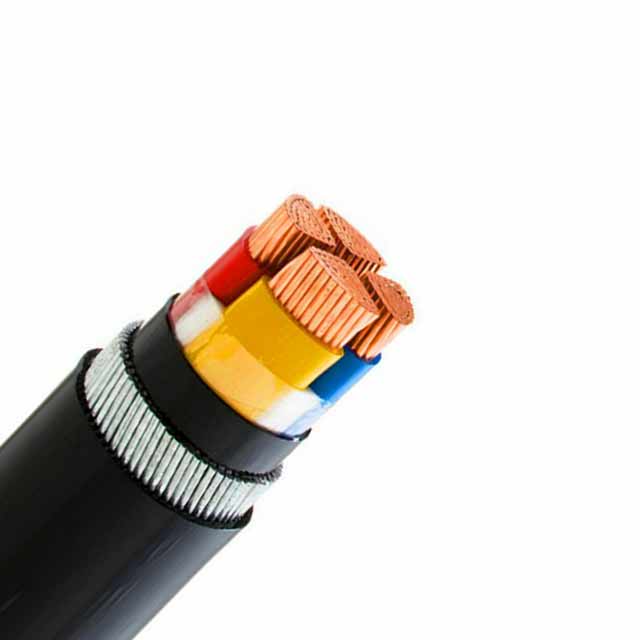

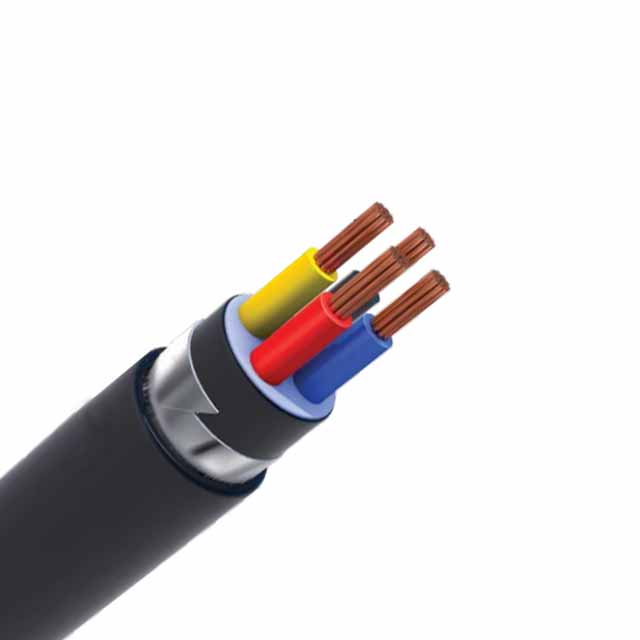

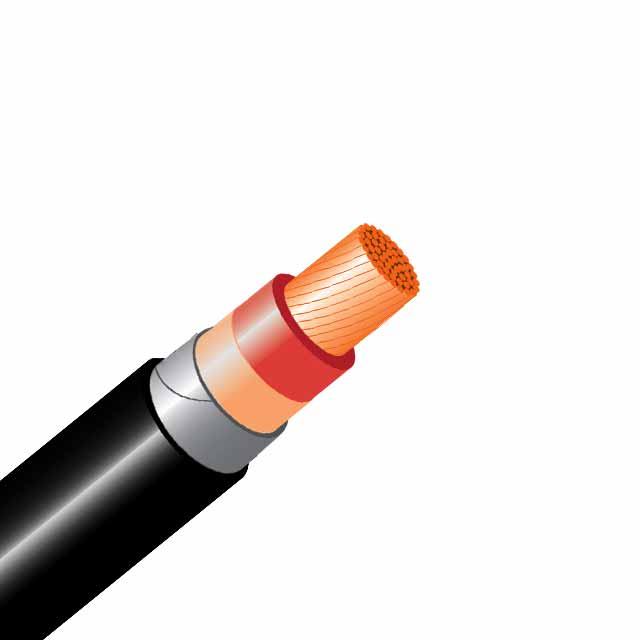

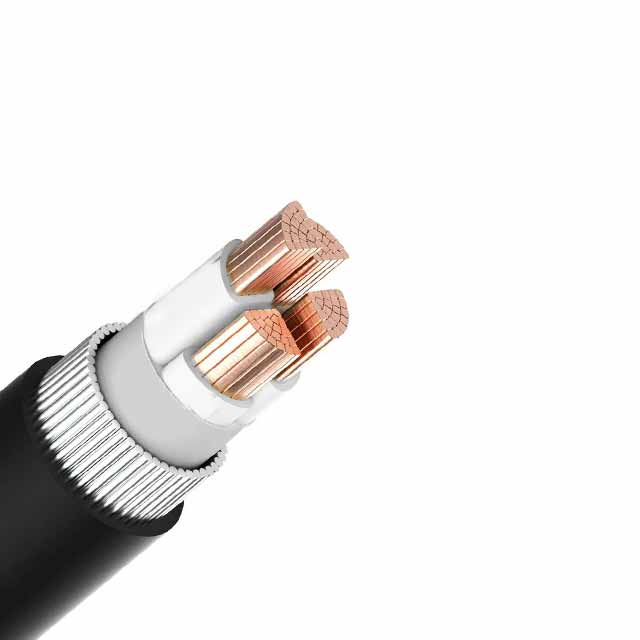

An aluminium conductor steel reinforced cable (AAC) is a high-strength stranded conductor commonly used in overhead power lines. High-purity aluminium outer strands provide excellent conductivity and are chosen for their low weight and resistance to mechanical stress and corrosion. Steel reinforcement is used for added strength and durability. AAC cable is highly durable and is available in a wide variety of colors.

ACSR is another name for ACSR (Aluminium Conductor Steel Reinforced). These cables are primarily used in power plants and transmission lines. The structure is unique in that the conductors are one layer of aluminum wire that undergo special processing. Because of its high strength-to-weight ratio, ACSR is particularly useful for applications where flexibility is essential. AAC cables also have excellent EMI and mechanical resistance.

ACSR cable is available in a range of strand counts and conductor diameters. Generally, utilities use a standardised conductor version to minimize the risk of hardware failure. However, they also skip some sizes to keep inventory costs down. Ultimately, the choice of conductor material depends on the needs of the application. It is important to choose the right one for the application. AAC cables are widely available.

ACSR cables have high hysteresis losses, a consequence of atomic dipoles moving in the steel core. An even number of aluminium layers reduces hysteresis losses. However, they are unable to overcome the heat associated with ACSR conductors. Consequently, ACSR cables are not recommended for high-voltage applications. But they are suitable for low-voltage applications, such as telephony lines.

CSA standards do not recognize the “M” family of zinc alloy coating materials. Hence, Canadian utilities use higher-strength steels. The conductivity of the steel core is included in the AC and DC resistance calculations, but is not included in the Canadian standards association. Therefore, it is best to check with your utility provider before selecting the best AAC cable for your needs. So, if you are still confused, read on!

ACSR and AAC are two popular types of cables used in electrical systems. Both are made from the same material – aluminium alloy containing between 5% and 10% aluminium. However, one of the major differences between the two types of cables is their core materials. ACSR is generally made of steel, while ACAR is made of aluminium alloy reinforced with steel. The latter is often referred to as Alumoweld.

ACSR cables are made of hard aluminum conductors, while ACAC cables are made of aluminium strands surrounded by zinc coated steel. Regardless of the type of conductor used, each type of cable can be configured to meet customer requirements. These cables have the same tensile strength, but they vary in diameter. ACSR cables can be twisted to meet specific electrical requirements. They can handle temperatures up to 250 degrees Celsius.

Another major difference between ACSR and AAC cables is the conductor. ACSR cables with odd-layered conductors have higher AC resistance, and are less economical. Even-layered ACSR cables have better power transfer efficiency than those with odd-layered ones. They also have less resistance than equivalent-diameter ACSR cables. This difference is largely due to the hysteresis effect, which is negligible for even-layered cables.

Compared to ACSR, AAAC cables have better corrosion resistance. Both are suitable for coastal and urban environments, but AAC cable is more expensive. AAC cable is often used in high-voltage transmission lines. This type of cable has a higher weight than ACSR. However, it also has higher electrical conductivity. It is also lighter than ACSR, and has a better strength-to-weight ratio. For electrical applications, the AAC conductor is better.

The AAC conductor is a type of aluminum product. It is made by stranding strands of aluminium. It is used in overhead power transmission and distribution lines with limited span length and small load-carrying capacity of the pole. AAC cable has similar properties to copper, but is cheaper and lighter. Its composition also differs from copper conductor. The latter is made of aluminium electrolytically refined.