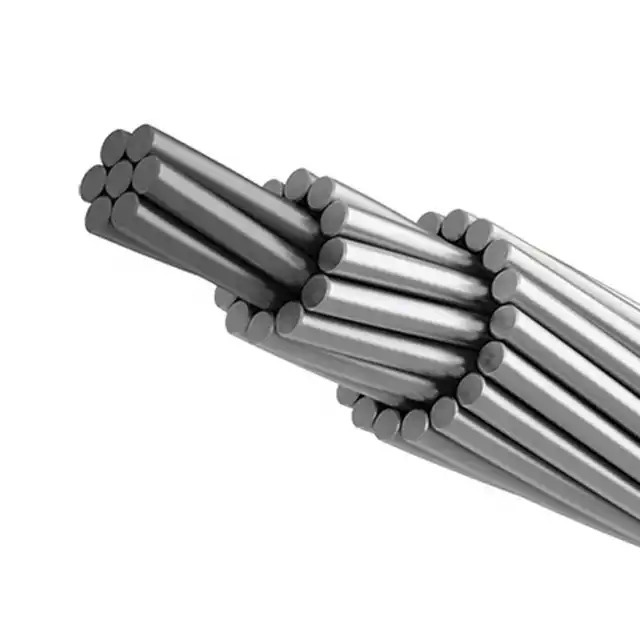

ACSR stands for Aluminium Conductor Steel Reinforced. It is a high-strength, stranded conductor, typically used in overhead power lines. High-purity aluminium is the outer strand, which is chosen for its excellent conductivity, low weight, and low cost. ACSR cables are also known for their resistance to mechanical stress and corrosion. This article will cover some of the more important points to consider before choosing this type of cable for your project.

Aluminium Conductor Steel Reinforced

The market for Aluminium Conductor Steel Reinforced (ACSR) cable is expected to surpass USD 3190.7 million by 2028, growing at a % CAGR during the forecast period. The report analyzes the market by region, product type, application, and competitive factors. The report also provides industry chain analysis and marketing strategies, which help to identify the opportunities and threats in the ACSR market. This report also outlines the key players operating in the market, including the leading manufacturers and the emerging market players.

Aluminium Conductor Steel Reinforced cable is a durable material that combines a steel and aluminium core. It is suitable for most applications, including sub-service and transmission tower spans. This material has an excellent strength-to-weight ratio, and a long service history. ACSR cables are available in both class A and class C. The benefits of ACSR over other materials include low cost, strength and reliability, and a low overall weight.

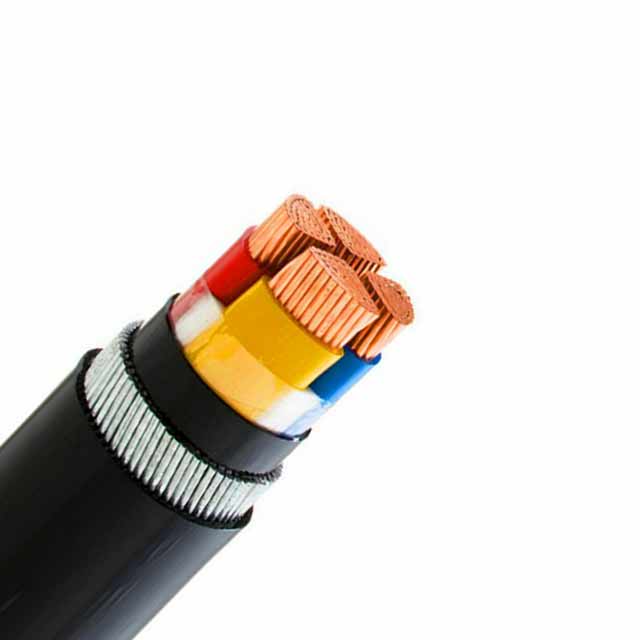

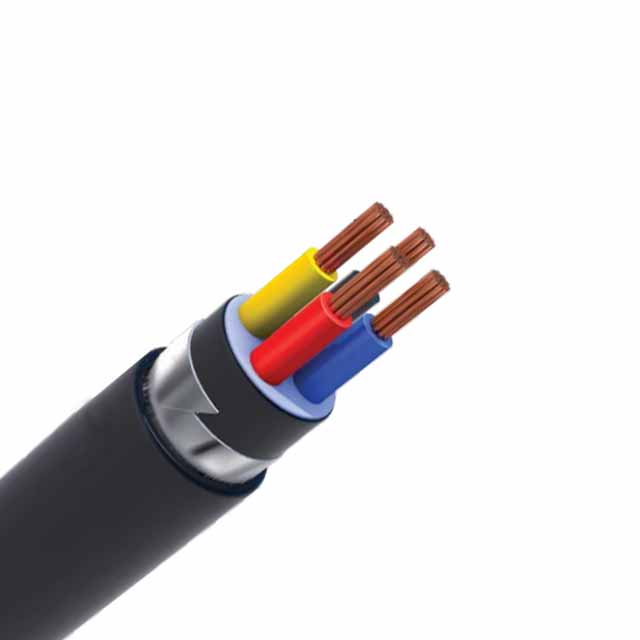

ACSR cables are stranded cables with an aluminium core surrounded by steel wires. They are used in electrical systems because of their strength and low weight. Aluminium and steel provide the same benefits, but with a more rigid construction. This construction enables ACSR cables to withstand high-tension loads, allowing them to operate at higher power levels. ACSR cables are used for overhead transmission and distribution lines due to their low weight and high strength-to-weight ratio.

Another disadvantage of ACSR cables is their hysteresis. This is due to the atomic dipoles in the steel core. As such, the cable’s continuous operating temperature is 75 degC, which is the temperature at which aluminium begins to soften. However, ACSR cables are suitable for use in temperatures as high as 250 degC. AWG cable strands contain more than one atom, so it is important to choose the right kind of stranding for the particular application.

Super conductor

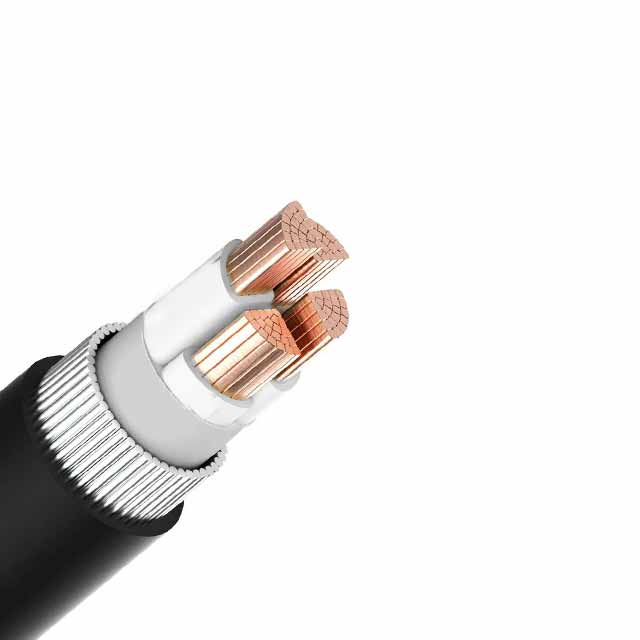

There are many different types of ACSR cables. In addition to the ACSR version, the cables can vary in strand diameter and the outer-most conductor strands can be either round or trapezoidal. The strands of the inner and outermost layers are usually round, while those of the intermediate layer are often trapezoidal. Each ACSR cable type has its own pros and cons, and it is important to understand them before purchasing a cable.

The major disadvantage of the conventional ACSR conductors in Examples 1 through 5 is that they have less optimal properties than the ones used in ACSR cables. By modifying the lay factors of the strand layers, the cable can attain better electrical and mechanical properties. Different properties will depend on the specific design criteria and application. Specifically, the new conductor configuration is designed to eliminate unbalanced torque and axial magnetic field.

Depending on the installation, higher-tensile ACSR is recommended for long-span overhead lines and river crossings. It is also lighter than other types of cable, so it requires fewer supports. Higher-tensile ACSR can achieve higher tensile strength without compromising ampacity. However, the strength of ACSR varies based on the percentage of steel core. There are other types of ACSR that use more aluminum and copper cores.

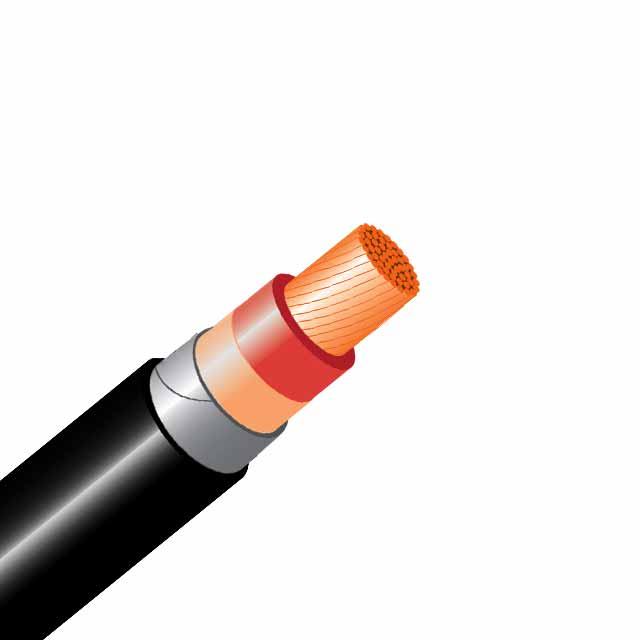

An ACSR cable can be manufactured with an oxide superconductor wire. These tape wires are spirally wound around a core member with an outer diameter of 30 mm. Each of the layers is separated by a thin 0.35-mm insulator. This construction allows for the cable to be manufactured using a variety of materials. Its high-quality ACSR cable will provide the best performance for your needs.

Instrument transformer

Instrument transformers are used for metering electrical quantities and to isolate instrumentation devices from the primary high voltage system. These devices have common laws for transformers, which are defined in IEC publication 60044-1. The wires used for connecting instruments and electricity measuring devices must have the proper gauge and polarity. Instrument transformers are generally rated for one to five Amperes. The following section describes the construction and use of instrument transformers.

A power transformer is a static piece of apparatus that uses electromagnetic induction to convert alternating voltage to current. It transmits electrical power, while an instrument transformer transmits information to meters, protective devices, and measuring instruments. Instrument transformers are available with rated voltages of 11kV to 500kV. They are also available with connectors that can handle 420kV. These transformers are often used in industries that require high voltage and a high amount of power.

An instrument transformer’s rating is determined by the load that is applied to it. This rating is expressed in kilovolts amperes, or VA. A voltage transformer with a rating of 10 VA should be operated with an instrument circuit drawing of 10/110 A. This is equivalent to the total resistance of the load across the secondary winding of 110 V. Likewise, the magnitude of the measurement error will determine how much power is provided to the consumer.

When disengaging from a current transformer, be sure to short circuit the secondary before disconnecting the primary. This prevents high voltage buildup across the secondary. To ensure safety, always short circuit the primary and secondary before disconnecting the instrument transformer cable. When the secondary is connected to a circuit, it should be isolated by the ammeter. Then, short circuit the secondary with switch ‘S’. This will prevent high voltage levels across the secondary.

Cost-effective

In addition to its flexible and pliable conductor, the ACSR wire is also lightweight and has low corona resistance. These features provide a significant advantage when it comes to high-voltage overhead lines. Additionally, ACSR cable prices are lower than those of other types of conductors. Those benefits make it the cable of choice for most transmission lines. In addition, the ACSR wire does not require as much maintenance.

High-capacity ACSR cables are typically used for overhead power lines. They feature a steel core strand that is surrounded by aluminum conductors for strength. This combination of metals ensures that the cables will last for decades without experiencing sagging or deterioration. Furthermore, the ACSR cable is incredibly flexible and withstands high temperatures without buckling or bending. With its high tensile strength, this type of cable can be used in a variety of applications.

The TP type of ACSR cable has a non-round conductor cross-section that helps reduce Aeolian vibration and fatigue-inducing strains. By gently rotating the conductor, it dissipates the energy. It also has the advantage of higher tension levels and fewer sags than a standard conductor. Nevertheless, the cost of the ACSR cable is more than double that of standard conductors.

The resistance of ACSR cable varies with frequency and the number of conductors. An even number of aluminium layers minimizes hysteresis losses, while an odd number of conductors eliminates the effect of the magnetic field on the cable. Nevertheless, a higher resistance is required for the odd-layer ACSR cable. The odd-layer ACSR cable has a hysteresis effect of up to 10%.

Less likely to break

While ACSR and ACSS are similar in appearance, the materials used to make them differ significantly in their electrical and mechanical properties. Both have a steel core and outer strands made of aluminum, but ACSS is made of a softer alloy of aluminum, or “O” temper. The aluminum in ACSR is tempered to be harder than ACSS, but the ACSS conductor is less likely to break because it behaves more like steel.

The aluminum conductor steel-reinforced cable has a concentrically stranded core made of aluminium wire. These wires are surrounded by steel strands, which give ACSR its strength and resistance to fatigue. The steel strands are available in Class A and B galvanized versions, which provide a high level of corrosion resistance. Because they’re stronger than steel wire, ACSRs are preferred for transmission lines.

The material used for ACSR conductors has different weights and breaking loads. Some ACSR cables are made of copper, while others are made of aluminium, steel, or both. This type of cable has a higher breaking strength than ACSR. ACSR cable also has higher resistance to electricity than ACCC conductors. If you’re considering buying an ACSR cable, there are many benefits to choosing ACSR.

ACSR cables are generally used in high-voltage applications. While a cable’s strength is measured in meters per second, its overall resistance is determined by the tensile strength. If the tension of the ACSR cable exceeds its capacity, it is more likely to break. ACSR cables have a low stress level, meaning they are less likely to break than other types of cable. This makes it safer for the environment, as they don’t have to be tied down to a steel or aluminum anchor.